Start > Industries > Electrical engineering and electronics

Electrical engineering and electronics

Conserving resources

It is well known that precious metals are needed for electronic components. But what can be done when more and more electronic components are used in everyday objects and the demand for precious metals increases as a result?

Precious metal recycling offers a good opportunity to deal efficiently with the available resources by recovering precious metals from electronic scrap or production waste. This benefits not only our partner companies for whom we perform this service, but also our environment.

See which materials are most common and which precious metals they contain in the list below.

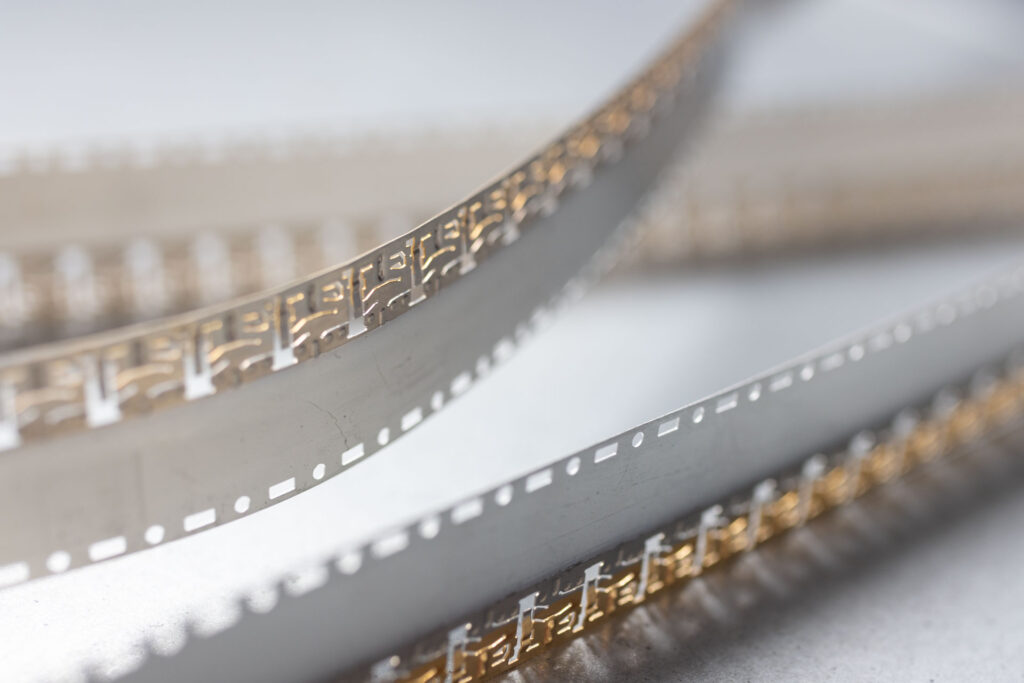

Metallic alloys

Metallic alloys accumulate on strip and punching waste during the coating of electronic components. Contact parts (twist-offs and pins), as well as ingots and melting pieces also contain precious metals. Wires, foils or sheets can also be coated with precious metals in the electronics industry.

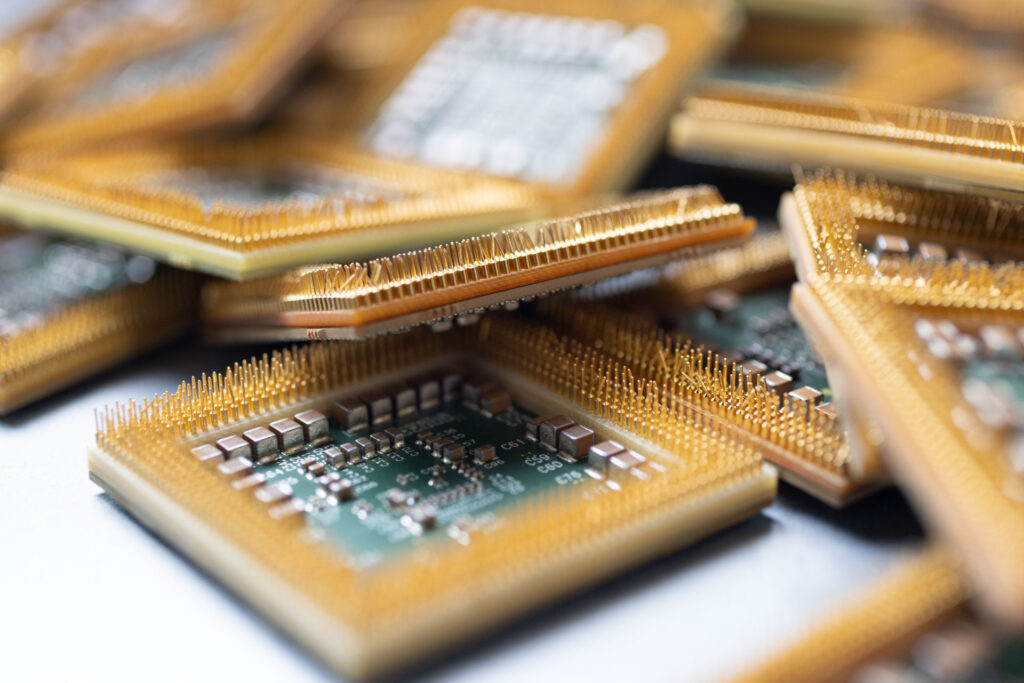

Ceramics

Thick-film circuits are used wherever high reliability is required and/or adverse environmental conditions prevail. Precious metal pastes are usually applied to the ceramics. Precious metals are also used in multilayer ceramic chip capacitors (MLCC). These are the most common type of ceramic capacitor.

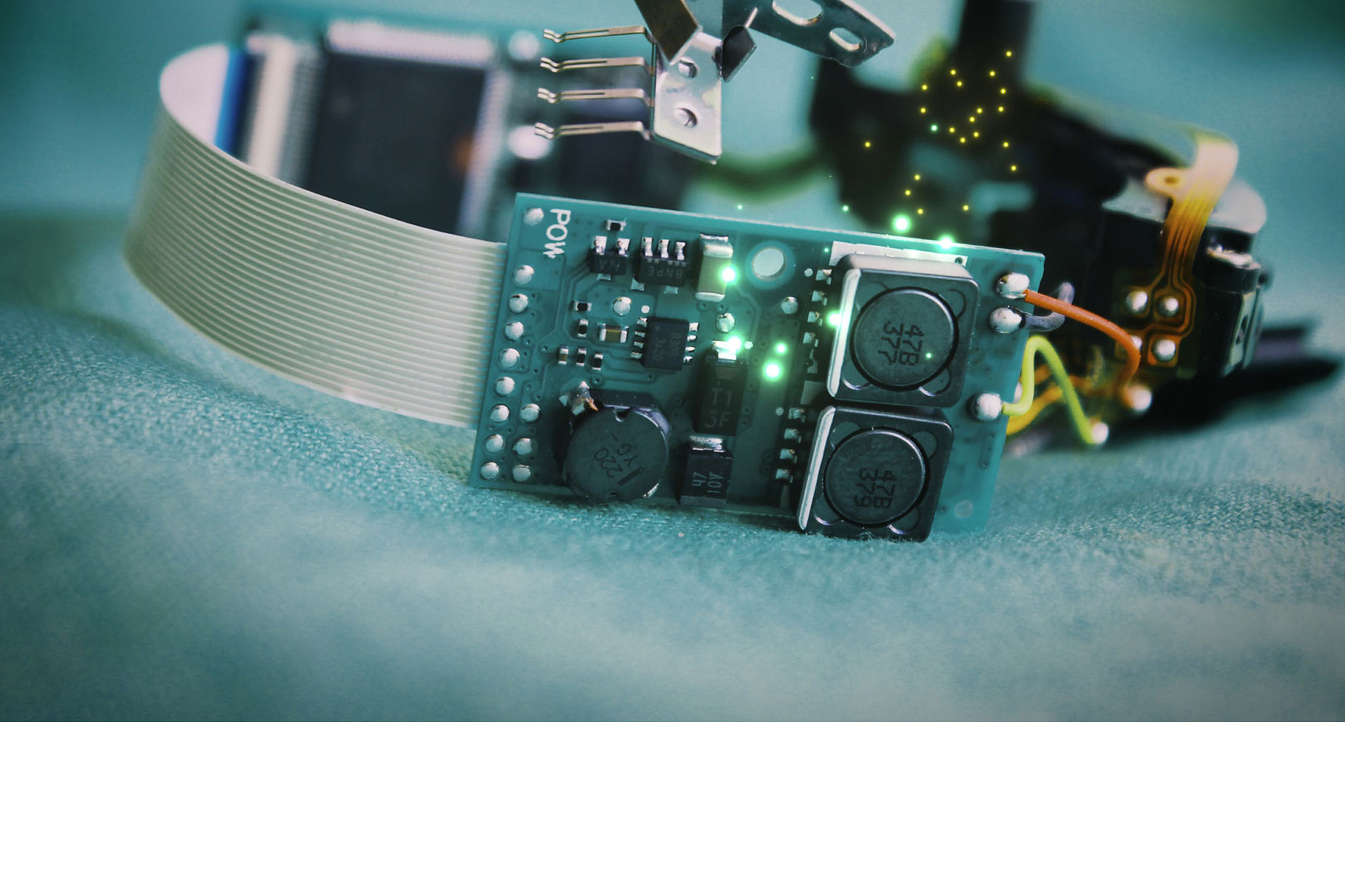

Composite materials

Electronic components such as processors, integrated circuits and electronic control units are not only part of the electronics industry, but have also become indispensable in the automotive sector. Semiconductors, connectors and foil circuits usually contain extremely high-grade precious metals.

Organic recyclable materials

Wiping cloths, sludges with solvent content, solder dross and other organic recyclables produced during the manufacture of ceramic circuits (hybrid ceramics) or various sensors contain precious metals. Solder paste cans, or cartridges that are opened, dried out or sorted out as ‘rejects’ after their expiration date also contain a high amount of valuable residual materials containing precious metals.

Precious metal baths, filters, resins from electroplating

Electroplating plants generate residual materials containing precious metals such as resins, sludges, baths, dross, filters, strippers, electrolytes, anode residues and production scrap.